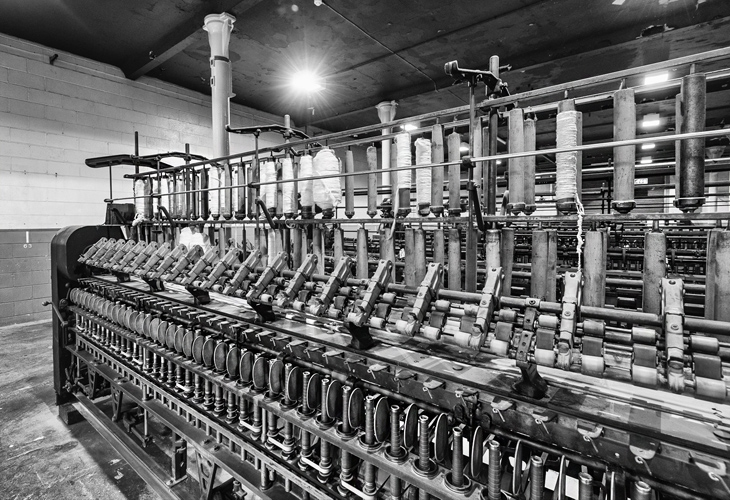

Photo-a-Day (Monday, 13th March, 2017)

Looming

Photo: Dave (Oy) (Nikon D800 with Nikon 16-35mm F/4 AF-S G VR)

Doesn't look like a loom to me Dave.

Great photo, having been a mechanical designer when I worked. that is some feat of engineering. Mind you I don't know if it is an old photo of a new loom or a new photo of an old loom

Now that's the "Way we were" literally. Excellent Dave, Black and White sums up the bygone era.

Wonder what any owd battery fillers on here will think of this photo?

I never worked in a mill but I wonder how the operators kept control of these machines, it always seems very daunting to me.

Is it a loom?

It looks more like a spinning frame to my untutored eye.

Confused, you are right this is indeed a ring frame for spinning cotton. Good photo though which works well in monochrome.

It's a Spinning frame to be exact, but they are fitted with cotton looms, there for all to see.

Lets not be picky!

Aged six, peered through a door off Mill Lane, Aspull, and saw rows of these clattering away spinning white cotton thread. The noise! No wonder mill workers talked with their hands!

Great photo.

I wonder how many 'Doffers' had to dart along relieving the frame of full spindles to keep that machine running at full pace?

I'm surprised Mick hasn't taken the opportunity to plug one of his videos.

Maybe tomorrow :)

Garry the spinning frames were never fitted with looms. The cotton was taken to the winding room where it was wound onto either beams for the warp or cones for the weft.Weaving was either done on site in the weaving shed, where they had one, or transported to another mill for weaving.

AP, when I was still at school I got a holiday job in Coppull Ring Mill and I was amazed at how many spindles the spinners could cope with. They not only changed the full spindles but jointed broken threads. Amazing workers, worthy of great respect.

Yes, I found this job description on line.

"DOFFER"

Job Description:

1) Doffs bobbins of yarn from spindles of spinning, twisting, or roving frames: Pushes button to stop machine and depresses pedal to lower ring bar, allowing yarn to wind around base of spindle to facilitate restarting.

2) Removes full bobbins of yarn from machine spindles, deposits yarn in handtruck, and places empty bobbins on spindles of machine.

3) Releases pedal to raise ring bar, starts machine, and pieces up breaks in roving or ties breaks in yarn ends.

4) Records information, such as doff time, date, and initials to complete company form.

5) Applies grease or oil to rings, using finger or oilcan.

6) May change travelers.

7) May brush waste from machine.

8) May be designated according to machine doffed as Slubber Doffer; Spinning Doffer; Twister Doffer.

Dave Ive had a look in my YouTube account https://www.youtube.com/user/singaporemick/videos and I cant find one from in there.

My mother was a 'doffer' I wondered what it was she did! Now I know....I think they used something to 'piece' the broken yarn with as well. I remember her coming home with cotton waste stuck to her hair. I sometimes went with her to collect her wages -and remember thinking I couldn't have done that job -the noise was horrendous. It felt claustrophobic to me. She always seemed to have chest problems caused by the cotton waste. It was a hard job but women seemed to like what they did.

click this link to see what they look like today.

http://www.ycfj.com/yuci_En/Product/SpinningEquipment/Frame/201011/W020101105616097806966.jpg

Hi guys I worked at Eckersley's for many years and the original loom was fed with warp and weft, the warp came off the beams and the weft was fed across the race board via a shuttle to produce the cloth.

spinning Room ,top half was for the roving bobbins , feeding through the rollers bottom half was for spinning the cotton onto the cops .minded by the trained lady called a spinner , and when the frame was full , it was stopped and the winder would come along to wind the cops to doffing level and then a team of Doffers (girls)would doff the full tubes off and replace empty ones on , hard work back breaking but such happy day x

I worked at May mill (Pemberton) up to it`s closing and one of the many jobs i did there this was by far the most enjoyable Oiling and Greasing all of the machines and it was none stop there was always something that needed doing, happy days and a great work force .