Wigan Album

Parsonage Colliery, Leigh

12 Comments

Photo: Keith

Item #: 28782

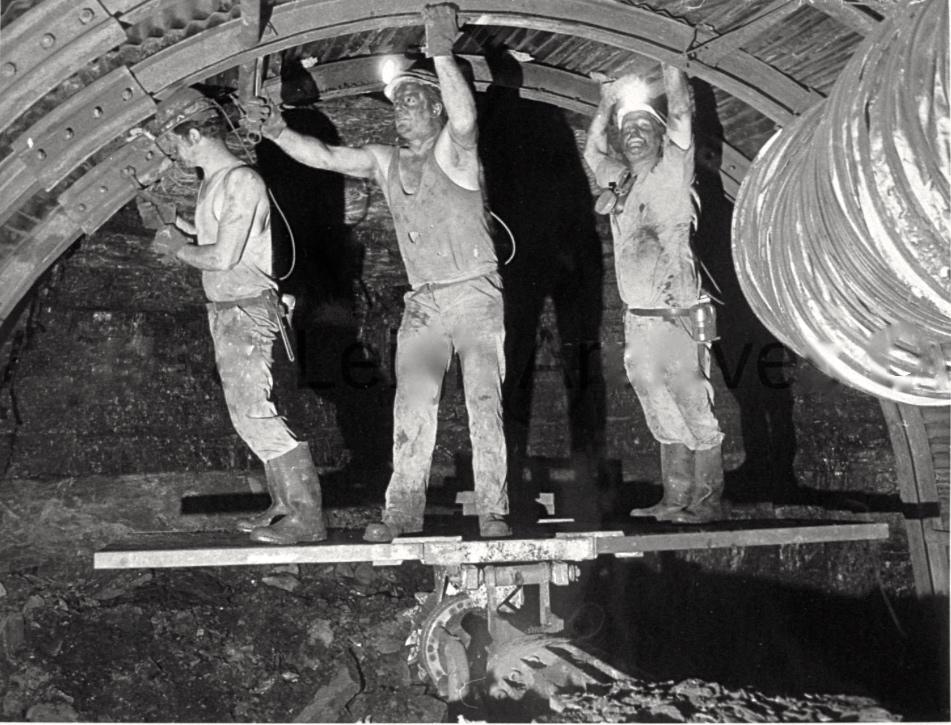

Doing the same job that I did in the early fifties, with the exception of those shown, using more advanced equipment. It really escapes me how we reached up to bolt up the fishplates in those days, although having said that, the arches that are being assembled seem to be larger than 14x10s. Those just had one set of fishplates in the centre of the arch. The support between the arches appear to be some type of corrugated metal sheeting. In the fifties, it was timber lagging boards.

Should have added. The ventilation system, that can be seen top right, is exactly the same that we had, by the time the air reached you, it had lost nearly all of its potency. The air could just about be felt, leaving the end of the tub, especially if the tunnel was quite lengthy.

It looks like a Dosco their using to drive the tunnel,and also stand on.

It sounds like you were setting clog irons Albert, that's what we called two piece arches. The arches in the photo are three piece, consisting of two legs and a crown held together by fishplates, and bolted to each other by metal struts.the miner in the centre is tightening one of the struts. The covering between the arches was usually corrugated steel sheets, timber lagging boards, or steel mesh.

I'm glad I didn't have to work down there, it looks quite frightening.

It's a Dosco Mk2 roadheader. It's possible that I assembled this very machine. The lad on the left looks like Colin Grainey, the one on the right looks like Jacky Critchlow and the big guy in the middle was (I think) called Jimmy also. He travelled from Blackpool every day if memory serves me correctly.

Albert you would have used two 4 inch RSJ girders on clamp runners one to the left and one to the right of the arches. then scaffold planks on top of the girders to stand on

I worked in a pub for a number of years as a youngster serving customers, many of whom had been or were miners. A few were seasoned drinkers but none of them were any trouble, nor did they complain or even mention the hard, dangerous work they they all undertook. If I could have my time back again I’d have loved to have talked to them about their work and perhaps the callow youth that I was would have gained a much better appreciation and respect for the men who did valuable work for the country in often such harsh conditions. On reflection not sure they would have appreciated me talking to them about their work after all they were in the pub to put that sort of thing behind them until they had to face up to it yet again the next morning. Heroes all.

Peter. As I remember it, the girders did not have any type of runner, you used the air pick to make footings for the end of the girder to rest in. In the footing you placed a piece of square wooden timber for the girder end to rest on. Once the arch had been completed, and all lagged, you drilled into the tunnel rock face. Drilled holes in the centre, holes on each side of the rock face, holes across the top, and then holes along the bottom. The fireman, or shot firer would then use delayed action shots to blast the rock face, middle first, then the sides, then the bottom, and then the top. all dropping on iron landings, to make the shovelling easier. Machines made it easier in later years, but it would still be dangerous, and very hard graft.

That really does look like one hell of a hard way to make a quid. Nothing but sheer respect for the guy's that performed this type of undertaking as employment.

Was Parsonage a wet pit, or was the wetness coming from the machines being used?.

Albert, during my time at Parsonage (72 - 81) the White & Black seam had a fair bit of water especially if we hit a fault. Nothing serious though and a Mono pump in the bottom end was usually enough to keep things moving.